Biocarbon is produced by the carbonization of ACTOF®, or other torrefied biomass, via pyrolysis. STC's patented, proprietary two-stage carbonization process enables the production of engineered biocarbon for use as a renewable reducing agent in metallurgical applications such as steelmaking, anodes for smelting, etc.

ACTOF® carbon will serve as a premium renewable, carbon-neutral substitute for metallurgical coke with lower ash, negligible amounts of sulfur, phosphorous, and other contaminants.

STC's proprietary processing system can also provide an engineered substitute for PCI (Pulverized Coal Injection) coal for use in blast furnaces known as PAI (Pulverized ACTOF® Injection) fuel.

Carbon can play a vital role in achieving ULCOS (Ultra Low Carbon Dioxide Steelmaking) objectives. Low ash, low sulfur, and low heavy metal properties of PAI will enhance blast furnace operational efficiency.

ACTOF® carbon and PAI fuels will provide sustainable, environmentally friendly steelmaking solutions for years to come.

Biocarbon for Pollutant Capture

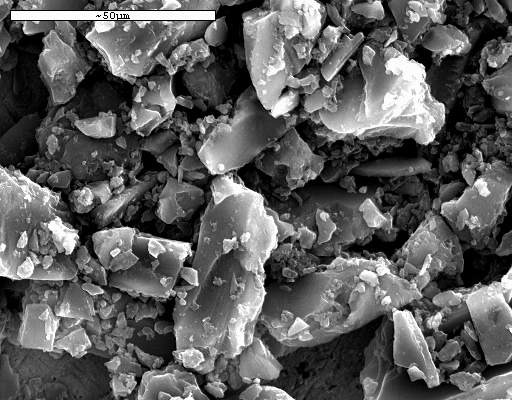

STC's proprietary two-stage carbonization process enables the production of an engineered, high fixed carbon (typically 80% dry basis) for producing pollutant capture products. We can utilize a variety of biomass feedstocks such as forest silviculture, agricultural residues, dedicated energy crops and other underutilized biomass resources and transform them into value-added engineered biomaterials.

ACTOF® carbon can be engineered to achieve desired physiochemical properties such as iodine number, butane activity, carbon tetrachloride activity, etc. via steam or chemical activation. Engineered ACTOF® carbon will be serve as a sustainable, renewable carbon feedstock for applications such as water purification, mercury scrubbing, air filters, gas purification, sewage treatment, etc.